Top 5 Applications of Industrial Steel Flanges

Industrial steel flanges are essential components in a variety of high-stakes industries, offering secure connections and reliable performance in extreme conditions. As the foundation of numerous piping systems, steel flanges help ensure safety, efficiency, and structural integrity across multiple applications. Below, we explore the top five industries that rely heavily on industrial steel flanges and discuss why these sectors demand high standards in flange manufacturing.

1. Oil and Gas Industry

In the oil and gas industry, the reliability of every connection is critical. Pipelines in this sector must handle high pressures, extreme temperatures, and hazardous materials. Industrial steel flanges are used extensively in pipelines, offshore rigs, refineries, and processing plants to ensure secure, leak-free connections.

- Why They Are Essential: In oil and gas, any leakage can lead to serious environmental and financial consequences. High-quality steel flanges meet ANSI standards to provide a tight seal under extreme conditions, preventing leaks and enhancing operational safety.

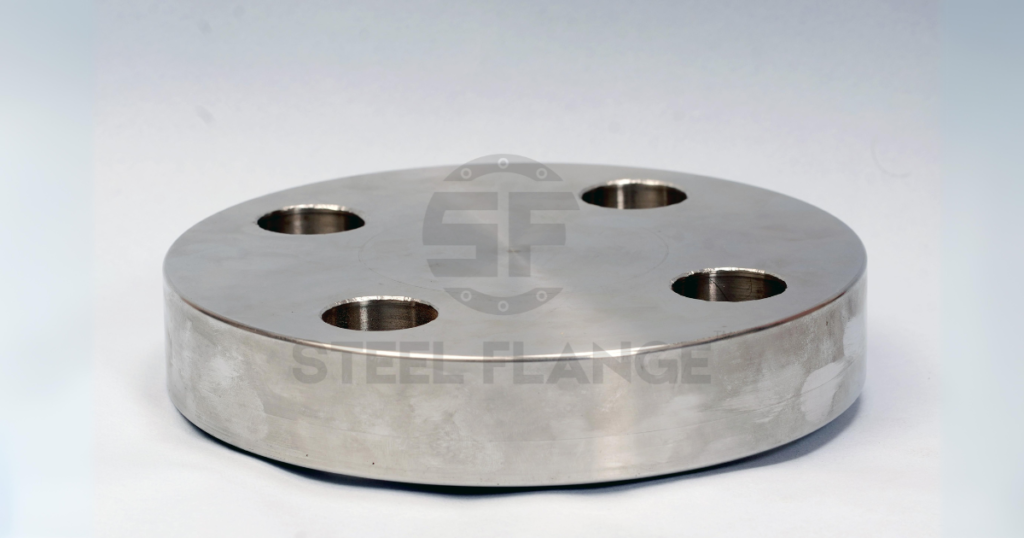

- Common Types Used: Weld Neck Flanges and Blind Flanges are often chosen for this industry due to their durability and ability to handle high pressure and temperature.

- Standards Compliance: ANSI and ASME standards are critical, as these guarantee flanges meet rigorous safety and compatibility requirements.

2. Petrochemical Industry

The petrochemical industry processes various chemicals and gases, which are often highly corrosive and reactive. Flanges in this sector must be able to withstand chemical exposure, high temperatures, and pressures while maintaining a secure seal.

- Why They Are Essential: Chemical processes often involve volatile substances that require high-quality connections to avoid contamination and potential hazards. Custom steel flanges made from corrosion-resistant materials, like stainless steel or carbon steel, are ideal for these applications.

- Common Types Used: Forged Steel Flanges and Stainless Steel Flanges are popular in petrochemical applications for their resistance to corrosion and high durability.

- Standards Compliance: DIN and ASME standards ensure that flanges meet necessary safety and performance benchmarks, allowing seamless integration with other piping components.

3. Waterworks and Wastewater Treatment

Waterworks and wastewater treatment plants rely on large networks of pipes to transport and process vast volumes of water. In these systems, flanges provide essential joints that allow for repairs, maintenance, and expansion without compromising the system’s integrity.

- Why They Are Essential: Flanges in waterworks systems must be durable and resistant to corrosion, especially in wastewater applications where pipes may carry corrosive substances. Stainless steel and galvanized steel flanges are common choices for their longevity and resistance to rust.

- Common Types Used: Slip-On Flanges and Lap Joint Flanges are frequently used in waterworks due to their ease of installation and maintenance.

- Standards Compliance: To ensure safe drinking water, flanges must meet strict health and safety standards, often following AWWA and ANSI guidelines.

4. Power Generation

In power generation plants—whether they are thermal, nuclear, or renewable energy facilities—piping systems transport critical fluids like steam, water, and coolants. The durability and precision of steel flanges play a vital role in maintaining the safety and efficiency of these systems.

- Why They Are Essential: Power plants operate under intense conditions with high pressures and temperatures, so flanges must be robust and reliable. Any failure in these connections can lead to significant downtimes and costly repairs.

- Common Types Used: Weld Neck Flanges and Socket Weld Flanges are preferred in this industry due to their strength and ability to handle thermal expansion.

- Standards Compliance: Flanges in power generation often adhere to ANSI, ASME, and DIN standards, ensuring they can withstand extreme conditions without compromising performance.

5. Food and Beverage Industry

The food and beverage industry uses flanges in processing and distribution lines for liquids, powders, and other ingredients. Here, flanges not only need to be durable but also compliant with hygiene standards to prevent contamination.

- Why They Are Essential: In food processing, flanges must provide a secure seal to prevent leaks while also being easy to clean and maintain. Stainless steel is commonly used for its non-reactive nature, preventing flavor or quality alteration of food products.

- Common Types Used: Stainless Steel Pipe Flanges and Sanitary Flanges are commonly used due to their corrosion resistance and ease of cleaning.

- Standards Compliance: Flanges in this industry must comply with FDA and ISO standards to ensure they are safe for food contact and prevent contamination.

Why High-Quality Industrial Steel Flanges Matter

Regardless of the industry, one thing remains constant: the need for high-quality, durable steel flanges. Choosing the right steel flange manufacturer is critical for ensuring that the products meet industry standards, are compatible with other piping components, and provide long-lasting performance.

Factors to Consider When Choosing a Flange Manufacturer:

- Quality Control: Ensure the manufacturer has rigorous quality checks in place.

- Compliance with Standards: Look for compliance with ANSI, ASME, DIN, and other relevant standards.

- Customization: Many industries require custom steel flanges to meet specific needs, so choose a manufacturer that can accommodate custom requests.

Conclusion

Industrial steel flanges are indispensable components across a range of industries, each with unique demands for durability, pressure tolerance, and corrosion resistance. Whether it’s securing oil pipelines or ensuring food safety in processing plants, flanges must meet stringent standards to support the high demands of modern industries. By working with a reputable steel flange manufacturer and selecting the right materials, companies can enhance the safety, efficiency, and longevity of their piping systems.

For more information on industrial steel flanges or to request a quote, contact Steel Flange MFG, your trusted flange manufacturing company for high-quality steel flanges.